Precision Services for Power Generation

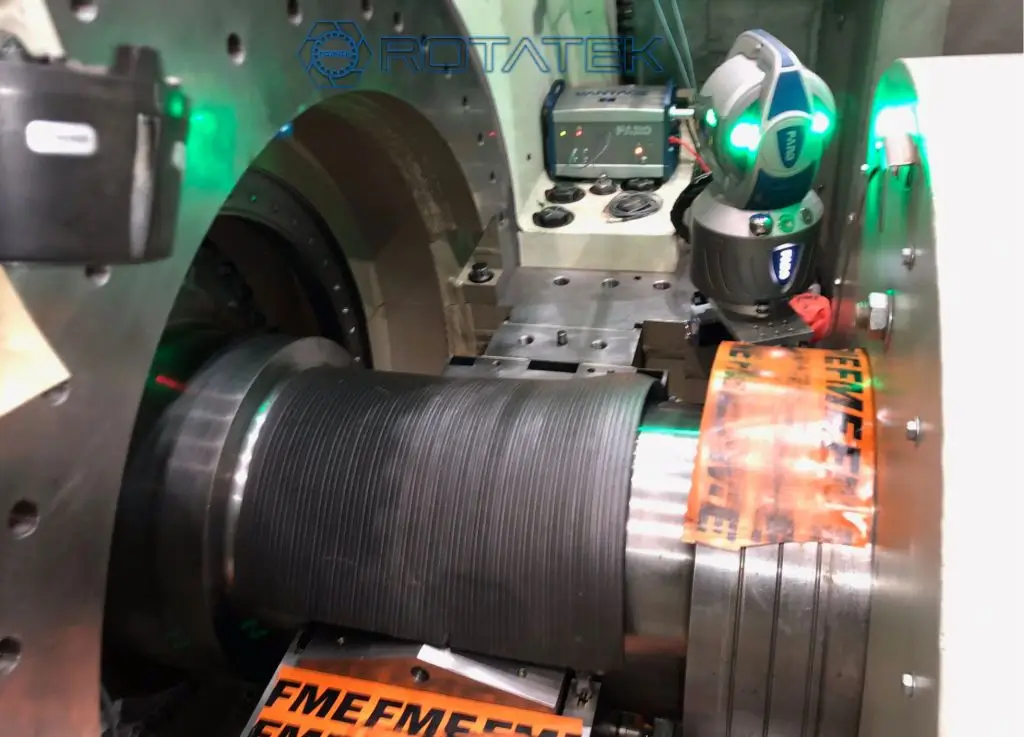

In the power generation industry, reliability isn’t optional—it’s mission-critical. At ROTATEK, we provide specialized laser alignment and 3D metrology services tailored to the demanding environments of power plants, utility stations, and energy production facilities. Our experienced technicians understand the precision required for aligning turbines, generators, gearboxes, pumps, and auxiliary systems that operate under extreme conditions and tight tolerances.

From fossil fuel and nuclear plants to renewable energy systems, we help reduce vibration, prevent premature wear, and support thermal growth compensation with precision solutions that minimize downtime and maximize output. Whether you’re performing routine maintenance, commissioning a new unit, or tackling an emergency shutdown, ROTATEK delivers fast, accurate, and repeatable alignment—backed by calibrated, NIST-traceable laser tracker technology and decades of field-proven expertise.

When your equipment powers cities and critical infrastructure, trust ROTATEK to keep everything aligned and performing at its best.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Expert alignment of steam, gas, and hydro turbines—including rotor-to-casing, bearing, and coupling alignments—to maintain peak performance and prevent premature wear.

High-accuracy alignment of generators, pumps, compressors, and rotating machinery to reduce vibration and extend equipment life.

3D Metrology and Laser Tracker Services

Large-scale, high-resolution measurements for turbine components, foundations, and structural alignment using NIST-traceable contact and non-contact laser trackers.

Thermal Growth and Movement Compensation

Alignment solutions that factor in thermal expansion, ensuring critical components remain in spec under full load conditions.

Flatness and Straightness Verification

Precision measurement of baseplates, soleplates, and skid-mounted equipment to confirm alignment readiness and structural integrity.

Laser shaft alignment for minimizing energy loss and bearing/coupling wear in high-speed rotating equipment.

Vibration Diagnostics and Troubleshooting

Assistance in identifying misalignment-induced vibration issues and recommending corrective actions to stabilize performance.

Laser Alignment: Ensure critical components like shafts, rolls, and couplings are aligned to micrometer precision, reducing wear and extending equipment life.

Dimensional Inspections: Verify complex part geometries and assemblies against CAD models or tolerances.

Reverse Engineering: Rebuild or redesign legacy parts and assemblies with confidence using high-resolution 3D scanning.

Documentation and Compliance Reporting

Detailed inspection and alignment documentation to support internal QA/QC processes and industry compliance requirements.

Emergency Field Support

Rapid-deployment alignment and measurement services for unplanned outages and critical failure events.

At ROTATEK, precision isn’t just a promise—it’s our certified standard. As an AS9100D and ISO 9001:2015 certified company, we back our commitment to quality with globally recognized benchmarks for excellence. With decades of field-proven expertise in precision measurement, laser alignment and 3D metrology, we deliver unmatched accuracy and reliability across aerospace, defense, power generation, marine, and general industry.

Our expert technicians adapt to the most demanding environments, offering tailored solutions with fast nationwide response times, 24/7 availability, and a proven quality management system built for mission-critical performance. We utilize cutting-edge equipment and industry-leading software to ensure your critical components meet the tightest tolerances—every time.