At ROTATEK, our 3D Alignment and Precision Measurement services utilize advanced technologies and specialized tools to accurately align machinery and equipment within specified tolerances. We precisely position objects and components in three-dimensional space, which is critical for machinery, structures, and systems where misalignment could cause operational issues, inefficiencies, or safety hazards.

We deliver these vital alignment solutions across multiple industries—including power generation, aerospace, shipbuilding, manufacturing, and beyond—ensuring optimal performance, safety, and operational efficiency.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Overall, ROTATEK’s 3D alignment and precision measurement services ensure the reliability and efficiency of industrial equipment, reduce downtime, and help products meet stringent quality standards. Our skilled Field Service Engineers leverage deep expertise in metrology and precision alignment techniques to deliver consistent, high-quality results.

Surface Mapping

Surface mapping involves creating a detailed map of a surface to identify irregularities, deformations and deviations from the desired specifications. This is important in applications where surface quality is critical, such as in power generation, aerospace, shipbuilding, manufacturing and more.

Installations

Precision measurement services are often employed during the installation of new equipment or systems to ensure that they are positioned correctly and function optimally.

3D Measurements

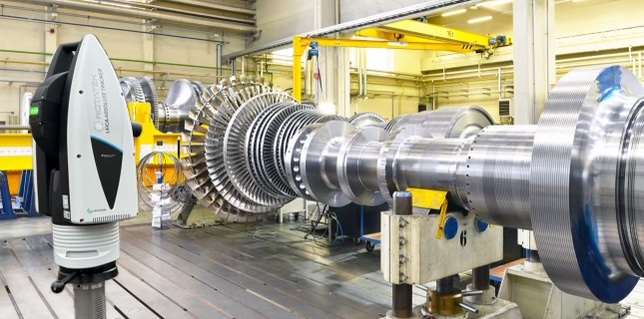

Laser trackers operate by measuring two angles and a distance. The tracker sends a laser beam to a retroreflective target held against the object being measured. As light is reflected off the target, it bounced back and re-enters the tracker at the same position it left and is measured by a distance meter, measuring the distance between the tracker and target.

The target returns the reflected laser beam parallel but offset back to the tracker where it hits the position detector, which calculates the offset between the outgoing and incoming beam. Servo motors continuously (thousands of times per second) steer the tracker’s head to minimize the offset between the two beams, resulting in high-speed, dynamic measurements.