At ROTATEK, we deliver expert vertical alignment services that ensure precise shaft positioning, improved machinery performance, and reduced maintenance costs. Whether it’s a vertical pump, motor, jack-shaft, or a full vertical machine train, our alignment solutions are engineered to correct misalignment at the source—before it causes bearing failure, seal degradation, or costly downtime.

Vertical machinery alignment presents unique challenges that demand more than just basic tools or visual checks. Gravity-driven sag, stacked component tolerances, and flange distortions can all contribute to angular misalignment—especially in critical applications like power generation, water treatment, and industrial processing. That’s why our team uses precision laser systems, real-time diagnostics, and proven alignment methods tailored specifically for vertical configurations.

From new equipment installs to post-maintenance verification, our vertical motor alignment, vertical jack-shaft alignment, and vertical machine train alignment services help eliminate vibration, extend equipment life, and keep your systems operating at peak efficiency. No guesswork. Just precision.

Trust ROTATEK to align your most demanding vertical systems—accurately, efficiently, and right the first time.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

At ROTATEK, we provide precision alignment for a wide range of vertical machinery and equipment. From vertical pumps to hydro turbines, our team understands the unique alignment challenges these systems present—and delivers proven solutions that reduce vibration, extend equipment life, and improve operational efficiency.

Industrial vertical machinery alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

Vertical MACHINERY Alignment

Vertical pumps rely on precision between the motor C-face and pump adapter. Despite flange fitting, angular misalignment is common due to machining variances or mounting surface distortion.

- Soft-foot check ensures foot-to-base contact before alignment

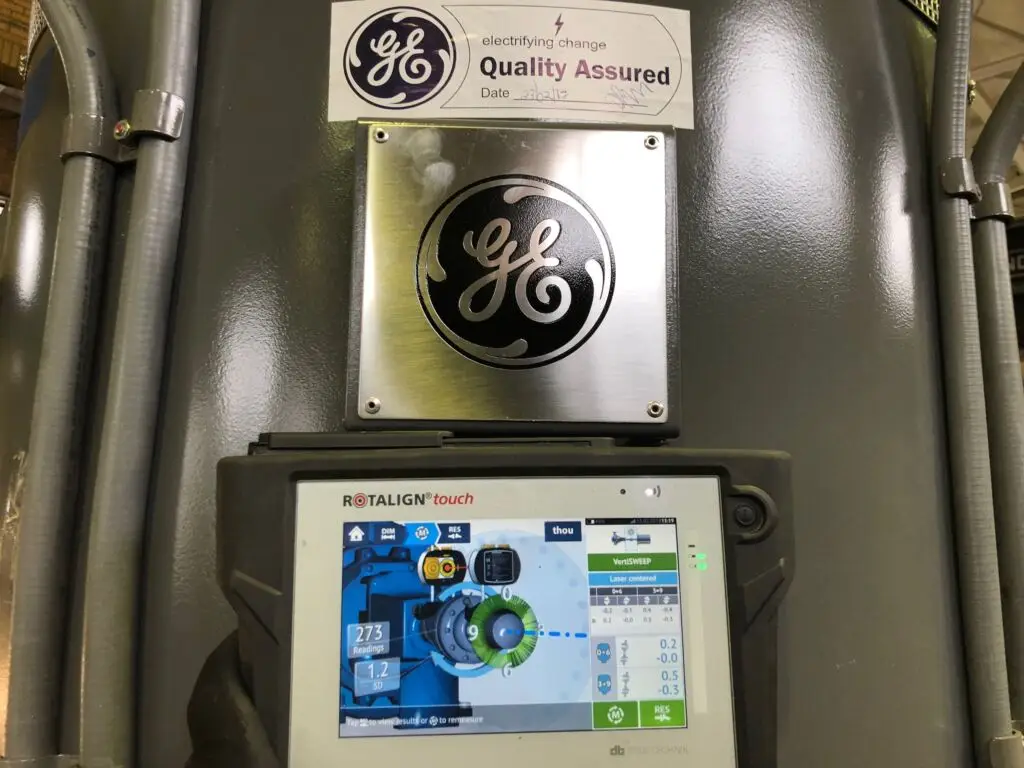

Use laser shaft alignment systems and laser tracker systems to inspect, level and align critical components.

Shim bolt locations to correct angular misalignment.

Verify angular and radial coupling alignment results are in-tolerance.

Vertical shaft Alignment

Jack‑Shafts – Spacer-Shafts, Cardan Shafts (long, intermediate shafts, offset shafts) need dual-end laser alignment.

Our alignment engineers use laser shaft alignment systems and laser tracker systems to inspect, level and align critical components.

Correct both X-axis and Y-axis planes for true shaft‑to‑shaft accuracy.

VERTICAL MACHINE TRAIN ALIGNMENT

Complex setups with three or more vertically mounted machines requiring precision alignment:

Simultaneously measure multiple vertical couplings with advanced laser alignment systems

Use virtual move simulation to plan shim and adjustment sequences that minimize bolt‑bound risk

WHAT IS VERTICAL ALIGNMENT?

Vertical Machinery Alignment is the process of aligning the rotational centerlines of vertically mounted machines.

Unlike traditional alignment methods using a straight edges, or dial indicators, ROTATEK field engineers utilize state-of-the-art laser equipment for unparalleled accuracy, precision and measurement acquisition time.

Industry Standards for Vertical Machinery Alignment

At ROTATEK, vertical alignment services are performed in accordance with recognized best practices and industry alignment standards. Where applicable, we follow ANSI/ASA S2.75-2021 Part 3, a national standard that specifically focuses on the alignment of vertically oriented rotating machinery. It defines the accepted criteria for shaft alignment tolerances, measurement procedures, and corrective actions—ensuring that your vertical equipment operates safely, efficiently, and within specification.

By aligning to this standard where applicable, we deliver consistent, repeatable, and auditable results that protect your machinery and optimize performance.

At ROTATEK, precision isn’t just a promise—it’s our certified standard. As an AS9100D and ISO 9001:2015 certified company, we back our commitment to quality with globally recognized benchmarks for excellence. With decades of field-proven expertise in precision measurement, laser alignment and 3D metrology, we deliver unmatched accuracy and reliability across aerospace, defense, power generation, marine, and general industry.

Our expert technicians adapt to the most demanding environments, offering tailored solutions with fast nationwide response times, 24/7 availability, and a proven quality management system built for mission-critical performance. We utilize cutting-edge equipment and industry-leading software to ensure your critical components meet the tightest tolerances—every time.