ROTATEK’s dimensional metrology inspection services are built to ensure your components meet exact design specifications and comply with industry standards. Using advanced portable coordinate measuring machines (PCMMs) and precision scanning technologies, we deliver detailed dimensional analyses that directly support your quality assurance and production goals.

Dimensional inspection services involve the precise measurement and evaluation of physical components to verify that all critical dimensions and geometric features fall within specified tolerances. These inspections are essential in manufacturing and quality control, helping teams confirm part integrity before assembly or shipment.

Dimensional metrology plays a vital role in maintaining the quality, reliability, and consistency of manufactured parts. By applying advanced measurement techniques, ROTATEK helps manufacturers detect and correct deviations early in the production process—reducing rework, minimizing waste, and ensuring full alignment with design intent.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

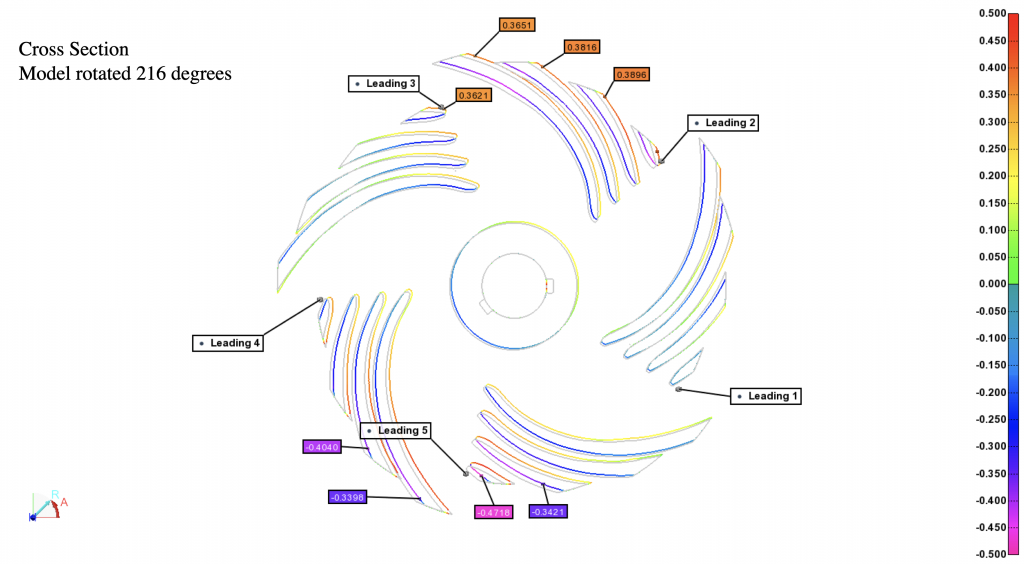

Part to CAD inspection involves comparing the dimensions and geometry of a physical part to its corresponding Computer-Aided Design (CAD) model. This ensures that the manufactured part aligns with the intended design.

GD&T (Geometric Dimensioning and Tolerancing) is a symbolic language used to communicate design specifications for parts and assemblies. It defines the allowable variations in form, orientation, location, and profile of features on a part.

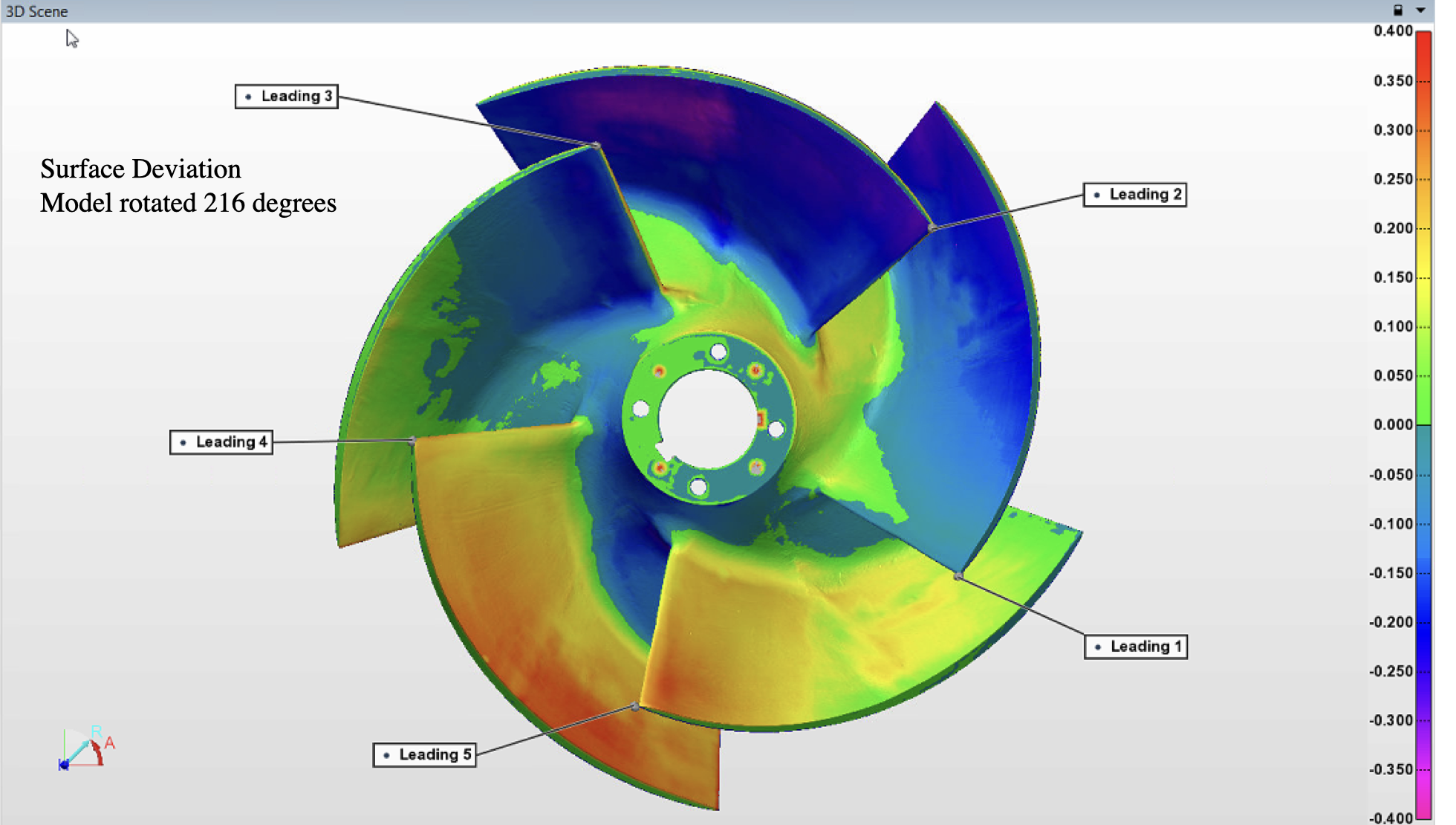

Surface mapping involves creating a detailed map of a surface to identify irregularities, deformations and deviations from the desired specifications. This is important in applications where surface quality is critical, such as in aerospace, medical and industrial manufacturing.

First Article Inspection (FAI) is a comprehensive review and verification process performed on the first production run of a new part or assembly. It ensures that the manufacturing process is capable of producing parts that meet the specified requirements.