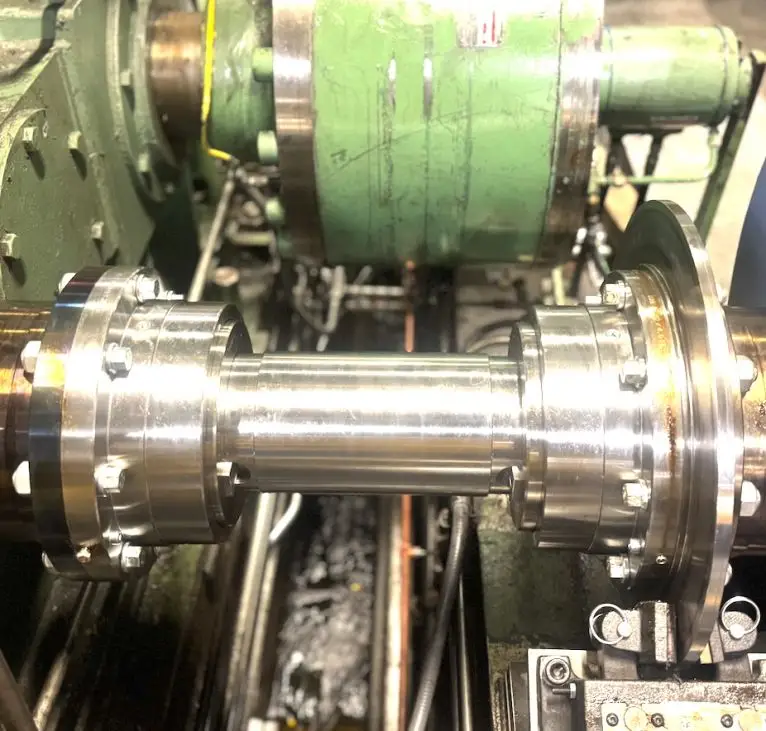

Precision Alignment for Critical Power Transmission

When your gearbox is out of alignment, it’s not just efficiency that suffers—it’s the entire drivetrain. Misalignment introduces vibration, increases bearing and seal wear, and shortens the lifespan of your most valuable mechanical systems.

At Rotatek, we deliver precision gearbox alignment using advanced laser systems and 3D metrology to ensure your gearboxes, motors, and driven equipment are perfectly aligned to OEM tolerances—or better.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Ensure your drivetrain operates at peak performance with precision gearbox alignment. Rotatek utilizes advanced laser and 3D measurement systems to correct misalignment, reduce vibration, and extend the life of bearings, seals, and couplings. From horizontal reducers to multi-stage gear systems, our solutions are engineered for durability, efficiency, and uptime.

Gearboxes are at the heart of power transmission in nearly every industrial application. Proper alignment of the gearbox input and output shafts is critical to:

Prevent premature bearing and seal failure

Reduce torque loss and energy consumption

Eliminate harmful vibration and noise

Improve load distribution across gear trains

Extend the service life of couplings and drive systems

Even slight misalignment can compound over time, leading to costly downtime and unexpected repairs.

Our gearbox alignment service is essential in:

Steel & Paper Mills

Power Generation Plants

Pulp & Paper Facilities

Mining & Bulk Material Handling

Marine Propulsion & Drive Systems

Industrial Manufacturing & Automation

Food Processing & Packaging Lines

Wherever high-torque systems rely on consistent rotational accuracy, gearbox alignment is mission-critical.

Horizontal and vertical gearboxes

Inline, offset, and right-angle configurations

Large reducers and multi-stage gear trains

Coupled motors, pumps, conveyors, extruders, and fans

Rotatek’s alignment engineers are trained in high-precision alignment using the industry’s most advanced equipment:

Initial condition assessment

Laser shaft alignment using sub-micron accurate tools

Soft foot and base condition correction

Thermal growth and offset evaluation (if needed)

Shim and move corrections to bring systems within tolerance

Post-alignment verification and reporting

You receive full documentation of alignment status before and after corrections, with precision data suitable for maintenance records and compliance aud

Experienced alignment specialists

Field-proven results across heavy industries

Portable, on-site service nationwide

Advanced laser and 3D metrology systems

Fast turnaround with minimal operational disruption

Whether you’re commissioning new equipment, troubleshooting vibration, or planning preventative maintenance, Rotatek ensures your gearbox and drivetrain are aligned for maximum reliability.

Eliminate Misalignment. Extend Equipment Life.

Let Rotatek align your critical gearboxes and restore full mechanical efficiency.

Book your service or request a quote today.