At ROTATEK, we deliver industry-leading gas turbine alignment and precision measurement services using the most advanced 3D metrology and laser alignment technology available. Our experienced field engineers perform internal bore alignment, rotor and casing alignment, bearing alignment, and more—whether during a planned outage or emergency service. By utilizing state-of-the-art laser tracker systems, we complete alignments faster and with greater precision, ensuring your turbine meets OEM specifications while minimizing vibration, maximizing efficiency, and extending equipment life.

From installation to overhaul and routine maintenance, our gas turbine laser tracker alignment services outperform traditional methods—reducing outage time, cutting costs, and optimizing resource efficiency.

Whether you operate in power generation, oil and gas, or industrial manufacturing, our expert technicians and advanced diagnostic tools are equipped to meet the most demanding alignment challenges.

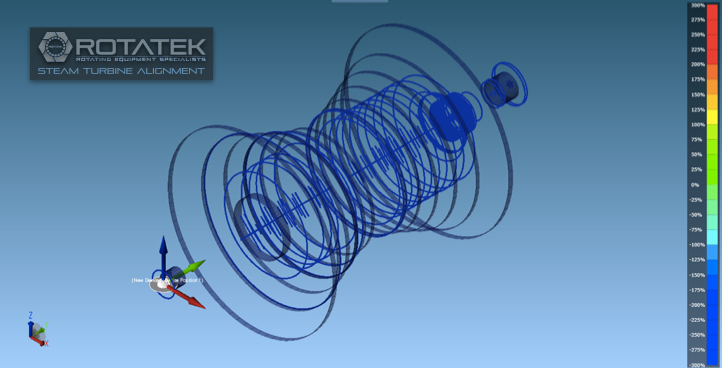

A detailed graphical measurement report is supplied with all precision measurement services.

Our commitment to excellence paired with our state-of-the-art measurement capabilities makes ROTATEK your trusted precision service partner.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

GAS TURBINE Alignment and Measurement Solutions

Gas Turbine Alignment is is critical to ensure that the rotor and stator components are concentric and that the axial and radial clearances between the rotating and stationary components are within acceptable limits.

Unlike traditional alignment methods using a straight edges, or dial indictors, ROTATEK field engineers utilize state-of-the-art laser equipment for unparalleled accuracy, precision and measurement acquisition time.

Industrial turbine alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

BORE ALIGNMENT

GENERATOR ALIGNMENT

MACHINE TRAIN ALIGNMENT

DYNAMIC MOVEMENT STUDY

FOUNDATION ALIGNMENT

GEARBOX ALIGNMENT

What We Align in Gas Turbines

Internal Components

Alignment of diaphragms, bearing pedestals, casing halves, seals, and stationary flow-path elementsRotor & Shaft Assemblies

Complete laser shaft alignment from compressor to turbine sections for balanced rotation and smooth coupling engagementGearbox & Generator Couplings

Precision alignment between the turbine, gearbox, and generator to optimize torque transfer and minimize vibrationFoundations & Baseplates

Leveling, flatness, and anchor position verification to support long-term alignment stabilityFull Machine Train Systems

End-to-end alignment of gas turbine, gearbox, generator, and driven loads for peak drivetrain reliability

Gas Turbine Alignment Services

3D Internal Bore & Casing Alignment

We use laser trackers to measure and align bore centers, casing halves, and internal stationary components to OEM tolerances. This helps maintain correct concentricity and prevents unwanted mechanical interference or flow disruption.

Ensures precise axial and radial positioning of diaphragms, seals, and flow-path hardware

Maintains rotor-to-stator clearances for optimal aerodynamic performance

Prevents premature wear, rubs, and flow losses caused by misalignment

Supports reliable rotor installation and efficient long-term turbine operation

Rotor & Coupling Alignment

We ensure precise alignment between the gas turbine rotor and generator shaft using cold or hot alignment methods, accounting for thermal expansion where necessary. Coupling misalignment correction reduces vibration and extends bearing life.

Reduces torsional stress and prevents premature coupling failure

Enhances bearing and seal longevity by minimizing misalignment-related loads

Improves system efficiency by ensuring smooth, balanced rotation

Thermal growth targets to maintain alignment during startup and full-load operation

Bearing Pedestal Alignment

Proper alignment of journal and thrust bearing housings prevents uneven load distribution and premature wear. Our laser tracking technology ensures these supports are precisely positioned in all axes.

Maintains concentricity between rotor and support structures for smooth rotation

Prevents edge loading, oil film instability, and bearing fatigue

Supports optimal rotor dynamics and vibration control

Ensures alignment is within OEM-specified geometric tolerances across vertical and horizontal planes

Dynamic Movement Study

Gas turbines experience movement due to thermal expansion, load shifts, and structural influences during operation. Our dynamic movement studies analyze positional changes from cold to hot conditions, allowing us to:

Measure growth, sag, and displacement across major components

Model thermal offsets and dynamic shifts

Predict and correct misalignment before full-load operation

Align shafts and couplings for optimal performance in real-world conditions

Foundation Alignment

A misaligned or uneven foundation can compromise the entire alignment chain of a gas turbine system. Our foundation alignment service verifies flatness, levelness, and anchor point positions using laser trackers or precision levels. Services include:

Skid and baseplate flatness checks

Anchor bolt and pedestal location verification

Leveling and correction analysis

Foundation movement monitoring during thermal or operational load

This ensures a stable base for all downstream alignment tasks and helps prevent long-term distortion or stress-induced failures.

Machine Train Alignment

Our comprehensive machine train alignment service ensures that all rotating equipment—gas turbine, gearbox, generator, and driven loads—are precisely aligned in sequence. Proper machine train alignment:

Minimizes vibration and mechanical stress throughout the drivetrain

Ensures efficient torque transmission and reduces coupling wear

Supports smoother startup and operational stability

Utilizes laser tracker and optical tooling for multi-axis precision alignment

By aligning the entire machine train as a system, we help maximize reliability and extend the life of your critical assets.

Reporting & OEM Compliance

All alignment work is documented in detailed as-found / as-left reports. We provide 3D measurement data, tolerance comparisons, and correction logs that meet or exceed OEM and industry requirements.

Why Gas Turbine Alignment Matters

In power generation, gas turbines operate under extreme thermal, mechanical, and rotational loads. Precision alignment of internal and external components is critical to ensuring performance, reliability, and safety. Misalignment—even by a fraction of a millimeter—can lead to cascading issues that reduce output and increase downtime.

Here’s why proper alignment is essential:

Minimizes Rotor Vibration & Fatigue:

Misalignment creates unbalanced forces across the rotor system, increasing vibration levels that accelerate bearing wear, shaft fatigue, and potential catastrophic failure.Preserves Bearing and Seal Integrity:

Journal and thrust bearings rely on precise axial and radial alignment to maintain proper oil film thickness. Misalignment disrupts hydrodynamic lubrication, leading to overheating and early failure.Maintains Aerodynamic Efficiency:

Internal flow-path components—such as diaphragms and seals—must be aligned concentrically to the rotor. Any misalignment increases clearances or causes rubs, reducing turbine efficiency and power output.Reduces Forced Outages & Downtime:

Uncorrected alignment issues often result in increased wear rates, elevated vibration alarms, and emergency shutdowns. Precision alignment during installation or outage mitigates these risks.Improves Thermal Behavior & Dynamic Response:

Gas turbines expand significantly during operation. Alignment practices that account for dynamic movement and thermal growth help maintain rotor-centerline geometry and coupling alignment under load.Supports OEM Compliance & Long-Term Reliability:

Turbine manufacturers specify tight alignment tolerances to ensure their equipment meets design life and performance targets. Professional alignment ensures those tolerances are consistently met and documented.

Integrated Metrology Solutions

We also offer complementary services that support your alignment needs:

Each of these services is designed to ensure your equipment, assemblies, and tooling not only meet design intent but perform to exacting standards.

Why Choose ROTATEK?

At ROTATEK, precision is more than a goal—it’s our standard. Backed by AS9100D and ISO 9001:2015 certifications, we uphold globally recognized benchmarks for quality in every service we deliver. With decades of hands-on experience in laser alignment, 3D metrology, and precision measurement, our team brings unmatched accuracy and reliability to every project.

We serve high-stakes industries including aerospace, defense, power generation, marine, and more—adapting to complex environments with speed, skill, and confidence. Our field engineers are available 24/7, mobilize quickly across the U.S., and operate under a robust quality management system designed for mission-critical performance.

We use the latest equipment and industry-trusted software—from FARO, LEICA, and PRUFTECHNIK—to ensure your components meet the tightest tolerances, every time.

Certified Quality

AS9100D and ISO 9001:2015

Always Ready

24/7 Availability & Nationwide Rapid Response

Advanced Tools

Industry-Leading Equipment: FARO, LEICA, PRUFTECHNIK

Proven Expertise

- Trusted Across Aerospace, Defense, Power Gen & Marine

Ready to Align with Excellence?

Contact us today to schedule your gas turbine alignment service or to discuss a custom solution tailored to your operational and equipment needs.