Advanced Vibration Monitoring with Vibguard

Real-Time, Multi-Channel Monitoring for Critical Rotating Equipment

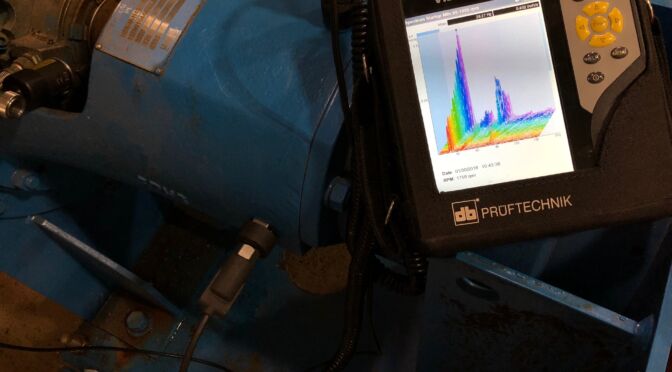

At Rotatek, we use cutting-edge technology to deliver deep insights into your machinery’s condition. Central to our monitoring capability is the PRÜFTECHNIK Vibguard® system—an advanced, high-resolution online monitoring platform designed for continuous data acquisition from multiple sensors across critical assets.

Rotatek offers condition monitoring service programs which are customized to monitor the condition of your rotating machinery to identify any significant change which is indicative of a developing fault.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

WHAT IS VIBRATION MONITORING?

Vibration monitoring is a process of continuously or periodically measuring and analyzing vibrations in machinery, structures, or systems to assess their health and performance. It involves the use of vibration sensors to detect and record vibrations, followed by data analysis to gain insights into the condition of the monitored equipment.

Vibguard® – High-Channel Vibration Intelligence

Each Vibguard® system can monitor up to 20 channels simultaneously, enabling comprehensive, real-time diagnostics on:

Rotors and shafts

Bearings and gearboxes

Pumps, motors, compressors, and fans

Complex multi-stage or coupled equipment systems

This multi-channel capability ensures no fault goes undetected, even in systems with multiple monitoring points or complex operating conditions.

OUR Vibration Monitoring Process

Sensor Installation

Vibration monitoring begins with the installation of vibration sensors, typically accelerometers, at specific locations on the equipment or structure of interest. These sensors measure the amplitude, frequency, and other characteristics of vibrations generated by the machinery’s operation or external forces.

Continuous Monitoring

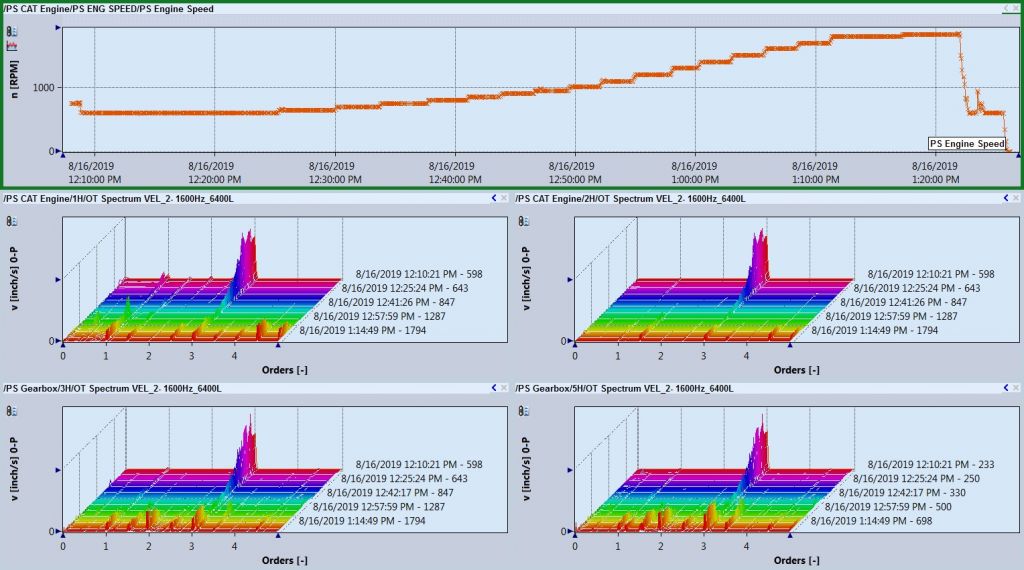

Vibration monitoring is a critical aspect of condition monitoring and predictive maintenance strategies. By continuously monitoring vibration levels, engineers can detect early signs of faults, misalignments, unbalance, bearing wear, and other mechanical issues. Early detection allows for proactive maintenance, reducing the risk of unexpected failures and costly downtime.

Data Analysis

The collected vibration data is analyzed to identify any anomalies, patterns, or trends that could indicate potential issues with the equipment. Frequency domain analysis, time-domain analysis, and other analytical techniques are used to interpret the data and extract meaningful information.