REAL-TIME Alignment Monitoring for Real-World Conditions

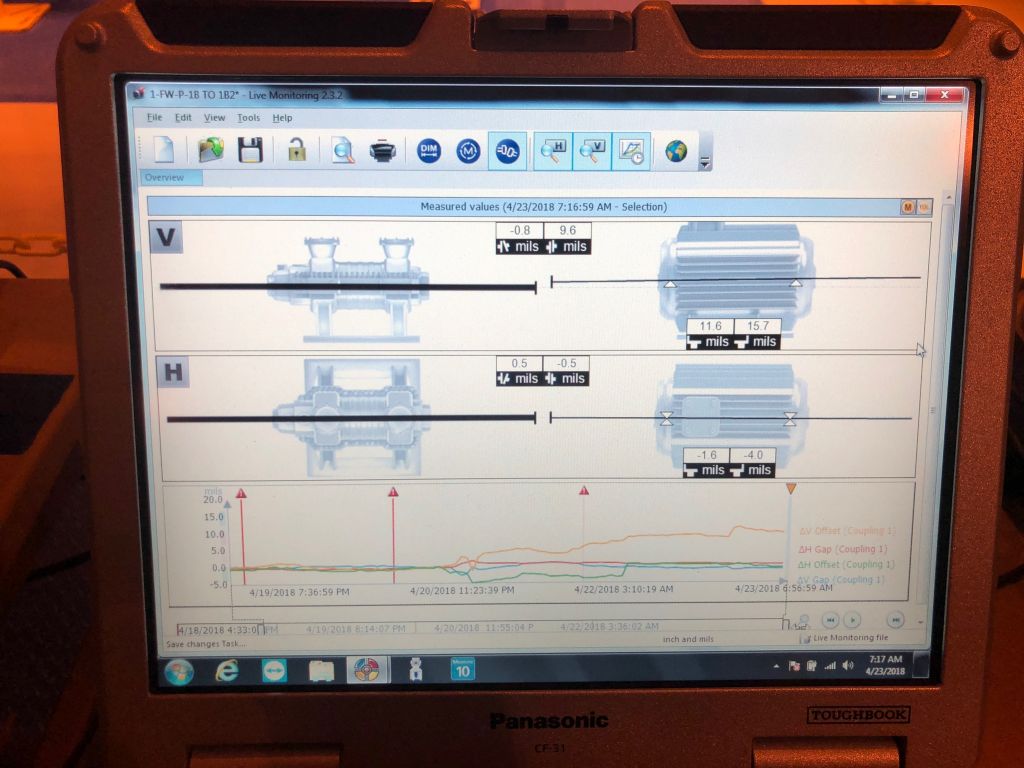

At ROTATEK, our Positional Change Monitoring services provide precise, real-time insight into how rotating machinery shifts during startup, sustained operation, and shutdown. By tracking thermal growth, dynamic movement, and overall positional change, we help clients understand how critical components move—from offline to running (OL2R)—and apply that data to optimize alignment strategies.

These real-world movements, often caused by heat expansion, structural deformation, and changing mechanical loads, can lead to significant misalignment if not accounted for during the initial setup. Our thermal growth studies, dynamic movement studies, and OL2R monitoring services are especially critical for gas turbines, steam turbines, compressors, and boiler feed pumps—equipment where precision is essential and reliability is non-negotiable.

While hot alignment has traditionally been used to compensate for thermal growth, it often falls short. By the time machinery is shut down and locked out for measurement, it can cool down enough to produce inaccurate alignment readings—making it a less reliable method than real-time OL2R monitoring.

Every ROTATEK service includes a detailed graphical measurement report to support compliance, maintenance planning, and engineering review.

With cutting-edge technology, field-proven methods, and a relentless commitment to accuracy, ROTATEK is your trusted partner for real-world alignment monitoring and performance optimization.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

ROTATEK provides a comprehensive approach to positional change monitoring, using advanced laser monitoring systems specifically engineered to track movement in the harshest environments as well as laser trackers, and laser shaft alignment tools.

Our services include:

Real-Time Positional Change Monitoring and Trending

-

Thermal Growth and Dynamic Movement Measurement

-

Dynamic Movement Tracking

-

Offline-to-Running (OL2R) Compensation – Using real-time displacement data to create precise alignment targets.

Vibration and Process Monitoring and Trending

-

Data Integration

TURBINE ALIGNMENT

Ensure optimal turbine performance and reliability with our precision alignment services. We offer expert on-site alignment, including casing alignment, bearing adjustments, and internal alignment, to maximize turbine efficiency and minimize downtime.

BOILER FEED PUMP ALIGNMENT

Ensure optimal efficiency and reliability with precision alignment of boiler feed pumps. Misalignment in these high-pressure systems can cause vibration, premature wear, and costly downtime.

COMPRESSOR ALIGNMENT

Precision alignment is critical to maintaining centrifugal, reciprocating and screw type compressor efficiency. Misaligned shafts can lead to increased vibration, bearing damage, and seal wear.

SHAFT ALIGNMENT

Ensure optimal efficiency and reliability with precision shaft alignment. Misalignment in rotating machinery can cause vibration, premature wear, and costly downtime.

Equipment Used for Positional Change Monitoring

To ensure the most accurate and reliable data, ROTATEK uses a suite of advanced measurement and monitoring systems, including:

Permalign® Laser Monitoring Systems – Real-time, continuous movement tracking across critical couplings, machines and structures.

Live Trend Monitoring Systems – Real-time monitoring of movement tracking across machine couplings.

Laser Trackers – High-precision, large-volume measurement systems ideal for machine, and structural movement studies.

VibGuard® Advanced Online Vibration Monitoring Systems – Multi-channel vibration monitoring and analytics for dynamic behavior diagnosis.

These systems allow us to capture high-resolution data under live conditions—enabling informed alignment decisions based on how machinery behaves, not just how it’s built.

At ROTATEK, precision isn’t just a promise—it’s our certified standard. As an AS9100D and ISO 9001:2015 certified company, we back our commitment to quality with globally recognized benchmarks for excellence. With decades of field-proven expertise in precision measurement, laser alignment and 3D metrology, we deliver unmatched accuracy and reliability across aerospace, defense, power generation, marine, and general industry.

Our expert technicians adapt to the most demanding environments, offering tailored solutions with fast nationwide response times, 24/7 availability, and a proven quality management system built for mission-critical performance. We utilize cutting-edge equipment and industry-leading software to ensure your critical components meet the tightest tolerances—every time.