Hydro Turbine Alignment is a crucial part of industrial maintenance that involves aligning multiple hydro turbine components to ensure optimal performance, reliability and efficiency.

ROTATEK provides internal, geometric and shaft alignment services for Francis, Kaplan and Pelton type hydro turbine machine trains.

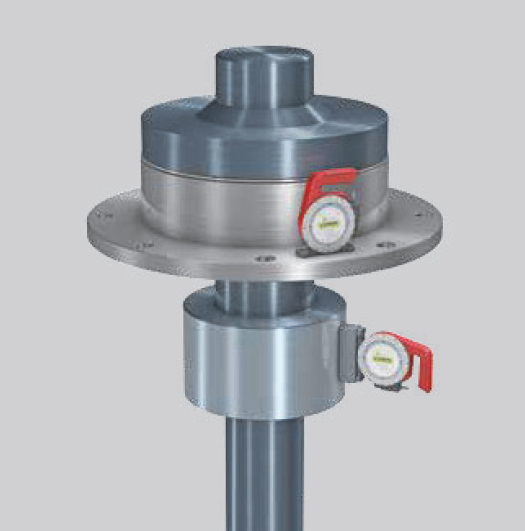

Our field service service engineers utilize a combination of state-of-the-art laser trackers and precision inclinometers specifically engineered for Hydropower Turbine Generator Alignment enabling us to to perform these services faster with higher accuracy and greater precision.

From installation to overhaul and maintenance, our hydro turbine alignment service solutions can out-perform traditional methods saving valuable outage time and resources.

A detailed graphical measurement report is supplied with all precision measurement services.

Our commitment to excellence paired with our state-of-the-art measurement capabilities makes ROTATEK your trusted precision service partner.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

HYDROPOWER TURBINE Alignment and Measurement SolutionS

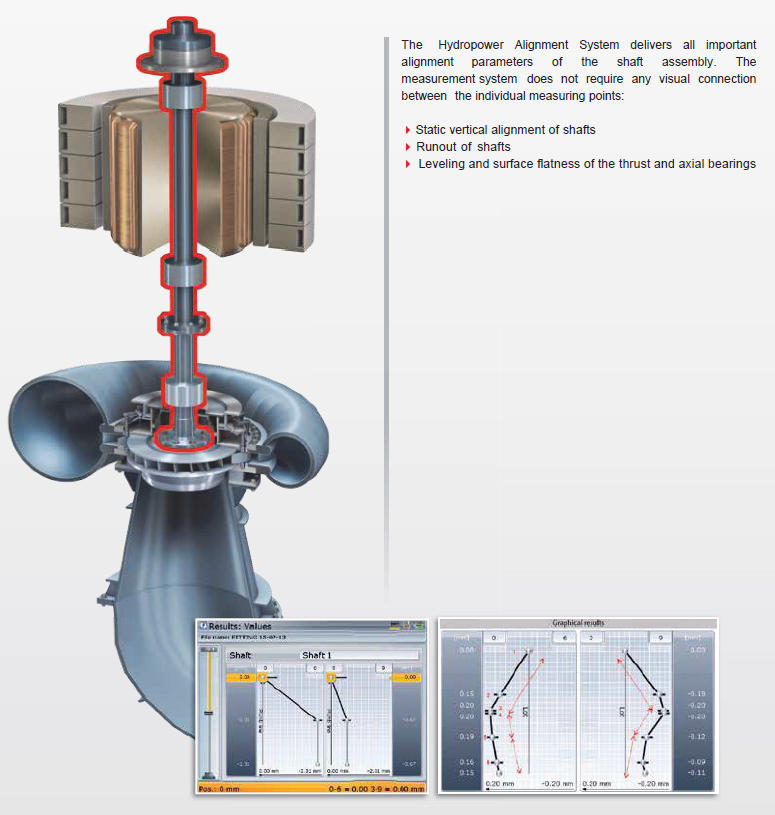

Rotatek offers innovative solutions for the installation, alignment and inspection of vertical hydropower turbines. Utilizing an application specific hydro power alignment system, NIST traceable laser tracker system, and precision measurement gauges Rotatek’s precision hydro turbine services offer significant advantages over traditional methods like plumb lines, spirit levels, and manual gauges.

Hydro Turbine Alignment is critical to ensure that the rotor and stator components are concentric and that the axial and radial clearances between the rotating and stationary components are within acceptable limits.

Unlike traditional alignment methods using a straight edges, or dial indictors, ROTATEK field engineers utilize state-of-the-art laser equipment for unparalleled accuracy, precision and measurement acquisition time.

Industrial turbine alignment is a complex process that requires careful planning, attention to detail and highly skilled operators in order to achieve accurate, reliable results in a timely and efficient manner.

Utilizing an application specific hydro power alignment system, Rotatek can measure angular deviations with high accuracy (often within arc-seconds), ensuring precise alignment of turbine components relative to gravity.

Alignment of the guide bearings and stationary machine components are easily measured no matter how large and precision moves can be monitored live.

Advanced laser tracker technology and innovative measurement solutions allows Rotatek to perform levelness and flatness measurements with unparalleled accuracy, precision and speed.

3D Measurements

Laser trackers operate by measuring two angles and a distance. The tracker sends a laser beam to a retroreflective target held against the object being measured. As light is reflected off the target, it bounced back and re-enters the tracker at the same position it left and is measured by a distance meter, measuring the distance between the tracker and target.

The target returns the reflected laser beam parallel but offset back to the tracker where it hits the position detector, which calculates the offset between the outgoing and incoming beam. Servo motors continuously (thousands of times per second) steer the tracker’s head to minimize the offset between the two beams, resulting in high-speed, dynamic measurements.