On-Site Dynamic Field Balancing for Smoother, Safer Operations

ROTATEK’s Dynamic Field Balancing services eliminate excessive vibration by correcting unbalance directly at your facility—no disassembly, no shipping delays. Our experienced ISO certified vibration analysts use precision balancing equipment to restore smooth operation for fans, motors, rotors, pumps, turbines, and other critical rotating assets. By reducing vibration at the source, we help extend bearing life, improve energy efficiency, and prevent costly machinery failures. Fast, accurate, and reliable—count on ROTATEK to keep your equipment in balance and your operations running strong.

how Can we Help you?

Our expert team is ready to help you with your next project. Explore the industries we serve or contact us to learn more.

Fast Response When Downtime Isn’t an Option

When critical rotating equipment fails or vibrates out of spec, every minute of downtime costs you production, money, and customer confidence. That’s why Rotatek offers rapid-response emergency field services for dynamic rotor balancing, complex alignment, and vibration diagnostics—available 24/7.

What is MASS UNBALANCE?

Mass unbalance occurs when a rotating component’s mass is not evenly distributed around its axis of rotation. This causes the center of mass (also known as the inertia axis) to shift away from the center of rotation (the geometric axis). When these two axes are not aligned, the rotor experiences unbalanced centrifugal forces during operation.

This misalignment creates a moment that causes the rotor to wobble, producing the characteristic vibration seen in unbalanced rotating structures. The result is often excessive noise, increased wear on bearings, reduced efficiency, and the potential for premature equipment failure.

In dynamic systems such as motors, fans, pumps, and rotors, even a small imbalance can lead to:

Decreased equipment lifespan

Higher energy consumption

Reduced operational efficiency

Costly downtime and maintenance

Field balancing corrects this imbalance by measuring the vibration and calculating the exact weight and location needed to restore equilibrium—without removing the rotor from the machine. This minimizes disruption and ensures optimal performance.

CAUSES OF ROTOR UNBALANCE

Rotor unbalance can develop from a variety of factors—either during manufacturing or over time through operational wear and environmental conditions. Common causes include:

Manufacturing Variations

Uneven material distribution, machining tolerances, or casting imperfections can create unbalance from the start.Assembly Errors

Misaligned components, improper fits, or asymmetric mounting of blades, pulleys, or couplings can introduce imbalance.Material Buildup or Loss

Accumulation of dust, dirt, or fluids—or the erosion of material due to wear—can shift the mass distribution over time.Thermal Distortion

Uneven heating during operation can cause the rotor to expand irregularly, changing the mass distribution.Component Deformation

Bending or warping of the shaft or rotor due to mechanical stress or fatigue leads to dynamic unbalance.Operational Wear and Tear

Long-term use can loosen parts, wear down surfaces, or lead to imbalance from asymmetrical degradation.

TYPES OF ROTOR UNBALANCE

Rotor unbalance is a condition in which the mass distribution of a rotating component is not symmetrical around its axis of rotation. This imbalance leads to centrifugal forces during rotation, causing vibration, noise, and potential damage to machinery. There are three primary types of rotor unbalance:

-

1. Static Unbalance

-

Definition: Occurs when the center of mass is offset from the rotational axis in a single plane.

-

Key Feature: Detected and corrected in one plane.

-

Effect: The rotor tends to rotate with the heavy spot always pulling down due to gravity.

-

Example: A disc with more mass on one side.

2. Couple Unbalance

-

Definition: Two equal but opposite unbalance masses are located in two different planes, 180° apart.

-

Key Feature: Net force is zero, but creates a couple (moment).

-

Effect: Causes a rocking or twisting motion of the rotor.

-

Example: A shaft with heavy spots on opposite ends but on opposite sides.

3. Dynamic Unbalance

-

Definition: A combination of static and couple unbalance; the most common type in real-world applications.

-

Key Feature: Unbalance exists in two planes, not directly opposite or equal.

-

Effect: Causes both lateral vibration and torsional effects.

-

Example: A long rotor like a turbine or pump shaft with uneven mass distribution along its length.

-

What is Dynamic FIELD BALANCING?

Dynamic field balancing is the process of correcting rotor imbalance while equipment is running at operational speed and location. By measuring phase and amplitude data using precision sensors and applying correction weights in the field, we bring unbalanced components back into spec—safely, efficiently, and with traceable results.

Unlike shop balancing, field balancing corrects the entire rotating system, including couplings, bearings, and structural effects—ensuring real-world performance.

OUR DYNAMIC FIELD BALANCING PROCESS

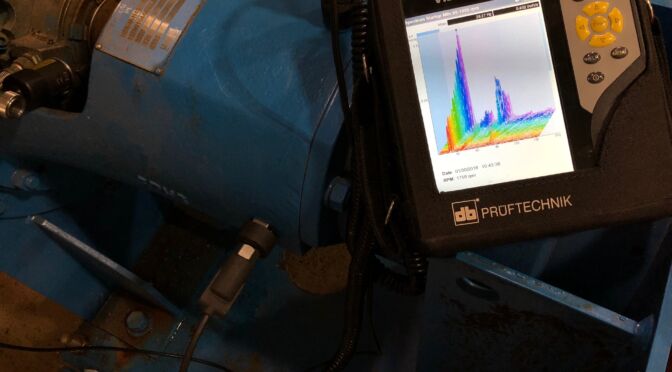

Site Assessment & Vibration Analysis

We identify vibration signatures and sources using high-precision accelerometers and data acquisition tools.

Phase Measurement & Diagnostics

Real-time phase angle analysis pinpoints the unbalance vector.

Corrective Action

We install and fine-tune balance weights to bring the system within tolerance.

Validation & Reporting

Post-balancing vibration readings are documented in a traceable report with before-and-after data.

DOCUMENTATION AND CERTIFICATION

All balancing services come with detailed traceable documentation, including:

Before/after vibration plots

Phase and amplitude records

Corrective actions taken

Compliance with ISO 1940 and industry balancing standards

We don’t just fix the issue—we prove it with data.

Precision Balancing for All Rotor Types and Mounting Configurations

At Rotatek, we offer expert dynamic balancing solutions tailored to a wide variety of rotor geometries and orientations. Whether you’re working with overhung fans, vertical pumps, or high-speed center-hung rotors, our team delivers traceable, field-proven corrections that enhance performance and extend equipment life.

Single Plane Overhung Rotor Balancing

Ideal for fan blades, impellers, and other rotors with mass concentrated at one end. We correct imbalance in a single correction plane, improving smooth operation and reducing shaft loading.

Common in HVAC, cooling towers, and small pumps

Performed using laser-tracked or accelerometer-based vibration tools

Quick correction without disassembly

Single Plane Center Hung Rotor Balancing

Used for symmetric, mid-mounted rotors such as certain grinding wheels and precision spindles. Balancing is performed on the rotor’s center axis for minimal runout and vibration.

Typical in machine tools and small-scale motors

Fine tolerances achievable on-site or in-lab

Ensures true centerline rotation

Dual Plane Overhung Rotor Balancing

For longer, heavier rotors where imbalance may exist in both the front and rear sections. Balancing is performed in two correction planes to eliminate both static and couple unbalance.

Common in industrial fans, multistage pumps, and blowers

Eliminates rocking motion and excessive bearing load

Essential for rotors with large axial length

Dual Plane Center Hung Rotor Balancing

Used in applications with high-speed or high-inertia rotors that demand precise balance in both planes. This method corrects for complex dynamic forces across the rotor body.

Ideal for turbines, compressors, and marine shafts

High-precision measurement and adjustment

Delivered with NIST-traceable documentation

Horizontal and Vertical Mounted Rotor Balancing

We support both mounting configurations using specialized fixtures and measurement techniques. Whether your rotor runs horizontally on pillow blocks or vertically mounted in a pump shaft, we adapt our process to the actual installation geometry.

Horizontal Balancing – More common, allows easy access and visual alignment

Vertical Balancing – Common in vertical pumps, generators, and thrust-mounted shafts

In-situ or off-site balancing based on equipment constraints